Why Electrostatic Spray Disinfecting is better than fogging, misting or wide area spraying

Electrostatic Spray technology for disinfectant application is being widely adopted as a tool to fight the COVID-19 pandemic. Now that the Delta Variant of the SARS-CoV-2 virus is causing a re-surgence of COVID-19 infections, disinfecting surfaces remains an important part in stopping the spread.

The spraying of surfaces with an electrostatic sprayer targets the spray droplets to uniformly cover even the most complex surfaces. This is in contrast to fogging and misting equipment that can only be used in evacuated spaces with areas required to be closed off for extended periods.

The COVID-19 pandemic has created a rush to market of different disinfecting products and application devices. The claims made by some products and various application methods has created immense confusion on what works and what may not.

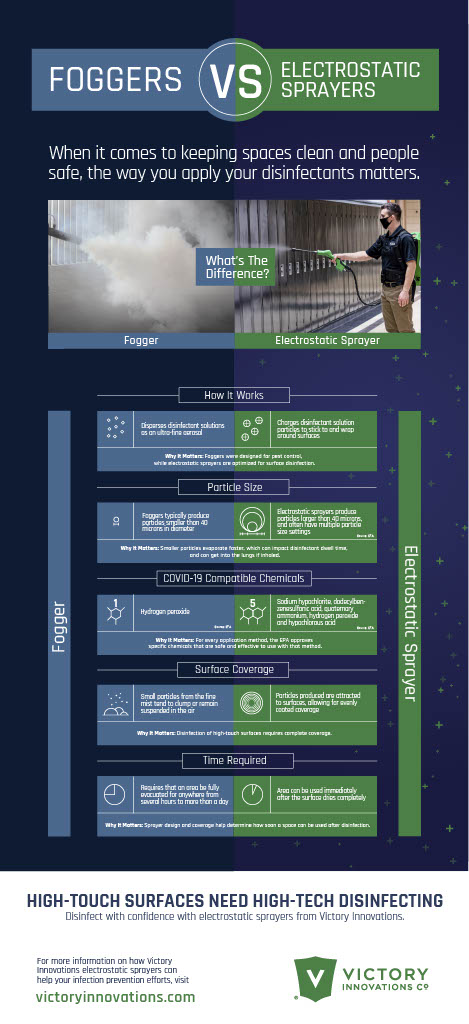

Electrostatic Sprayers vs other devices: We hear terms like fogging, misting, fumigating, wide area spraying and other terms when it comes to disinfectant application. Often used interchangeably, there is a big difference. Below and in the infographic one the right is an explanation of different application methods/devices and potential issues associated with each.

and other terms when it comes to disinfectant application. Often used interchangeably, there is a big difference. Below and in the infographic one the right is an explanation of different application methods/devices and potential issues associated with each.

- Fogging: This is a process where a solution (usually a disinfectant) is placed into a device that emits very fine droplets into the air which is visually apparent as a fog. Droplet size of the fog particulates is around 2- 5 microns. Here the fog is supposed to uniformly deposit on all surfaces. For reference, 1 micron is 1 millionth of a meter (a meter is roughly equivalent to 1 yard). Areas to be fogged must be closed off, evacuated of occupants, and remain closed to occupants for an extended period. Occupancy delays after fogging is around 2 hours.

- Misting: Misting is similar to fogging, in this case the droplet size is a little larger than fogging, estimated to be around 5-25 microns. Like the fog, the purpose is to keep the solution suspended to allow for slow deposition on surfaces. Like fogging, misting must be done in an enclosed space with an extended period before the space can be re-occupied. Occupancy delays after fogging is around 2 hours.

- Wide Area Spraying: Wide area spraying could use a mechanical device, pressurized sprayer or hand held trigger sprayers to atomize a liquid into spray droplets. Spray droplets are estimated to be 40-200 microns. These devices generally point a nozzle toward the surface to be sprayed in order to cover the surface. This method is often characterized by a large amount of overspray waste as many of the particles miss the target.

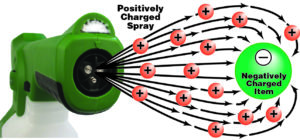

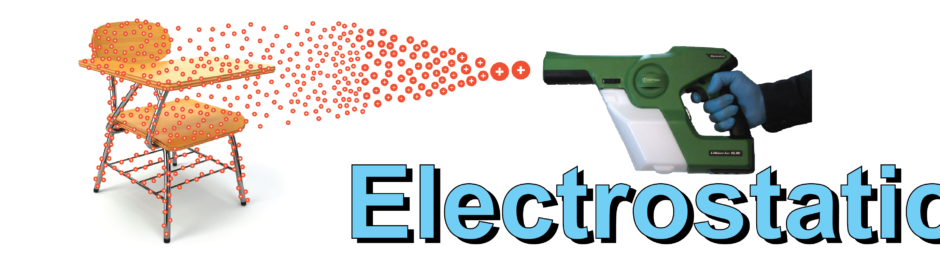

- Targeted Spraying: An electrostatic sprayer adds an electric charge to the spray droplets so they are naturally attracted to the surfaces being sprayed. Each charged liquid particle is attracted to a surface much like

opposite poles of a magnet. This targeted spraying results in less wasteful overspray and more uniform coverage. Droplet size is 40-110 microns. Occupancy delays are short with spraying, as you only need to wait until surfaces are dry, usually less than 15 minutes.

opposite poles of a magnet. This targeted spraying results in less wasteful overspray and more uniform coverage. Droplet size is 40-110 microns. Occupancy delays are short with spraying, as you only need to wait until surfaces are dry, usually less than 15 minutes.

What does the EPA say about fogging or misting? The EPA has expressed concern that fogging or misting of disinfectants may not be as effective as claimed. According to the EPA, “Application by fogging/misting results in much smaller particle sizes, different surface coverage characteristics, and potentially reduced efficacy when compared to sanitization or disinfection product applications by spraying, sponging, wiping or mopping”.

What is the EPA saying about electrostatic spraying? The EPA is still studying electrostatic spraying of disinfectants and has recognized the value of using this technology to apply disinfectants. The EPA is asking for submission of some additional data on electrostatic spray application of disinfectants. One piece of data is a “wetness” test to insure surfaces sprayed with an electrostatic sprayer remain moist that is consistent with the recommended contact time associated with the disinfectant being used. Due to the COVID-19 pandemic, the EPA is offering expedited review of data submitted, but it may still take months to get final review.

Below are some tips for using a disinfectant with your electrostatic sprayer.

- Use an electrostatic sprayer with an adjustable droplet size nozzle to adjust the wetness of the surface to correlate with the contact time of the disinfectant. The E-Spray electrostatic sprayer has 3 droplet size settings, 40, 80, and 110 microns.

- Use a disinfectant with a contact time less than 10 minutes. Multi-Clean 128 E-Fecticide is a concentrated, hospital grade disinfectant with a contact time of only 5 minutes. Use 40 micron nozzle setting to insure the surface stays wet for 5 minutes.

- Use a disinfectant that indicates “spraying” is a suitable method of application on the label.

- Consider using a concentrated disinfectant that you dilute with your own water to maximize cost savings. Typical Ready to Use (RTU) products contain more than 99% water.

- Finally, make sure the disinfectant you are using is approved on the EPA’s List N for disinfectants effective against SARS-CoV-2, the cause of COVID-19.

More Information: Visit our E-Spray Electrostatics Webpage

My dad is planning to hire an industrial coating service that would be able to spray his fading forklift. Well, thank you for clarifying here that fogging could be an effective solution since this may help device very fine droplets. Although, it interesting to learn that the targeting spraying will add an electric charge.