How Electrostatic Spray Disinfecting (E-Spray) can help slow the spread of COVID-19

COVID-19 is impacting life in ways we never imagined, Electrostatic Spray Disinfecting can help slow the spread.

On March 11, 2020, the World Health Organization declared the COVID-19 outbreak caused by the Novel Corona Virus (SARS-CoV-2) a Pandemic. After government mandated shutdowns of many businesses and institutions this spring helped flatten the curve of COVID-19 hospitalizations, cases are again rising at an alarming rate forcing a new round of shutdowns.

Mask mandates, social distancing, food take out only, online shopping, zoom meetings, and contactless deliveries, are just a few of the changes that will remain with us after COVID-19 is a distant memory.

Federal Reserve Chairman Jerome Powell summed it up this way in a recent speech saying:

“We’re not going back to the same economy. We’re recovering, but to a different economy and it will be one that is more leveraged to technology, and I worry that it’s going to make it even more difficult than it was for many workers.”

Stopping the Spread of COVID-19 is Job 1 and Electrostatic Spray Disinfecting can Help

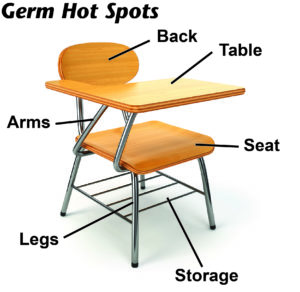

Even the best efforts at sanitation can fall short when a highly contagious virus like the human corona virus SARS-CoV-2, the cause of COVID-19 is running rampant. Some surfaces harboring germs simply get missed because they are complex in shape or maybe hard to reach. Think about a tables and chairs or a student desk, the top surface is easy to clean/disinfect, but what about the underside, the seat, rails, and legs?

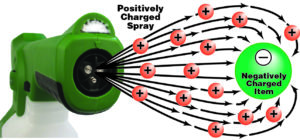

Furthermore, cleaning staffs often have limited time to cover large areas where traditional spray and wiping methods take a substantial amount of time. Enter the electrostatic sprayer or E-Spray, a special type of sprayer that charges disinfectant spray droplets so they are attracted to surfaces similar to opposite poles of a magnet. A battery powered electrostatic sprayer can cover large surface areas up to 20,000 sq ft/hour while insuring coverage of all critical surfaces.

What makes electrostatic spraying different from other types of sprayers?

When an object is sprayed with a Conventional sprayer (including a trigger sprayer), a portion of the spray particles reach the target object. The rest of the liquid particles succumb to gravity and fall to the floor or simply float past the object. Further, surfaces of complex objects or hard to reach spots are often missed. These missed spots can be a breeding ground for pathogens.

Electrostatically applied liquids have a wrapping effect, so that complex objects and areas hidden from the line of site get coated with the liquid. The E-Spray technology has been successfully used in other industries including agriculture and industrial painting.

Some electrostatic sprayers have adjustable nozzles to control the wetness of the surface and correlate it to the necessary contact time of the disinfectant. For electrostatic spray application, the droplet size of the charged liquid particle should be a

minimum of 40 microns or greater. Adjustable nozzle sprayers typically allow for spray droplet sizes of 40 microns, 80 microns, or 110 microns.

40 microns = disinfectant contact times 1-5 minutes; 80 microns = disinfectant contact times of 5-10 minutes.

Can I use any disinfectant in my electrostatic sprayer?

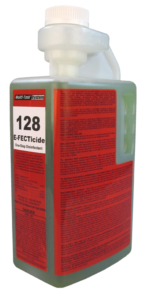

While many disinfectants may work in electrostatic sprayers, it is best to use the product recommended by the chemical manufacturer that sells the sprayer and produces the appropriate disinfectants.

Here are questions you may want to ask when selecting a disinfectant for an electrostatic sprayer:

- Is the disinfectant ready to use or a concentrate? Ready to use products are typically 99.5-99.7% inactive (inert) ingredients. Concentrated products can save 80-98% over ready to use products.

- What is the wet contact time for the disinfectant? Disinfectants can have wet contact times of 1-10 min. Using appropriate nozzle adjustments on the sprayer can help insure the contact time is met.

- Is the disinfectant listed on EPA List N-Disinfectant approved for Corona Virus (COVID-19)? Note that household bleach is NOT on EPA list N and should never be run through an electrostatic sprayer. Look for products that have an emerging pathogen virus claim, these are products proven to kill viral pathogens more difficult to kill than human corona virus.

- Is the product EPA approved for spray applications? Coming Soon…. The EPA has recognized the value of electrostatic spray application of disinfectants and has initiated an approval process to add electrostatic spray application to the label of certain EPA registered disinfectants.

When, where, and how to use E-Spray electrostatic spray equipment for disinfecting

Offices: Spray desks and chairs at the end of the day.

Conference Rooms: Spray tables and chairs after each use.

Classrooms: Desks, shelves, tables at the end of day or between class change overs.

Cafeteria: Spray all tables, chairs and other surfaces outside the kitchen.

Public Transportation: Buses, vans, taxi’s, light rail, Spray at the end of day or between route change overs.

Car Dealerships, Car Repair, Car Rental: Treat vehicles prior to customer pick-up.

Restaurants: Spray in between guests or end of day, include public areas, lobby’s, restroom partitions and other common touchpoints.

Public and Private Businesses: workspaces, offices, lobbies, conference rooms, community areas

Industrial-Warehouse & Manufacturing: End of day employee work stations, between shifts, employee  breakrooms, equipment, conveyers, and other machinery.

breakrooms, equipment, conveyers, and other machinery.

School Buses: Spray Seats, walls and rails between routes.

School Gyms: Wrestling Mats: prevent cases of MRSA and Ring Worm. Workout equipment, weights and other equipment.

Health Clubs: Barbells, weight machines, fitness equipment.

Locker Rooms: Metal lockers in side and out.

Restrooms: Spray partitions, behind toilets and other difficult to reach surfaces.

E-Spray: Another tool in the Infection Prevention Toolbox.

Electrostatic sprayers are only a small piece of the puzzle for stopping the spread of COVID-19. However, it can be a critical component of an overall infection prevention strategy for a facility.

E-Spray application of disinfectants gives building occupants, visitors, students, staff and customers the confidence that the necessary steps are being taken to keep people safe.

The Infection Prevention Toolbox should include the following:

- Encourage hand washing especially after using the bathroom.

- Locate hand sanitizing stations where water is not available.

- Policies requiring Sick workers/students/staff should stay home if feeling ill.

- Anyone experiencing COVID-19 symptoms should get tested and not allowed to return to work until recommended quarantine time has passed per CDC Guidelines.

- Implement a High Touch Surface Disinfecting Program.

- Regularly clean and disinfect surfaces.

- End of day or between use consider electrostatic spray disinfecting of surfaces.

Resources: Visit our COVID-19 Resource page where we have collected valuable guidance documents from the CDC and EPA. https://www.multi-clean.com/training/covid-19-resources/

What do you have to remember with Electrostatic Sprayers?

E-Spray electrostatic spray application of disinfectants is not a substitute for cleaning surfaces.

E-Spray electrostatic spraying disinfecting is another productive tool to help slow the spread of COVID-19 and other contagious illnesses.

Multi-Clean is a manufacturer of EPA registered disinfectants, cleaning chemicals, floor maintenance products and offers the battery powered E-Spray Electrostatic Sprayer in Hand Held and Backpack models.

Visit us at www.multi-clean.com